Conveyor Systems

Products on a pallet seems easy enough but when you are dealing with the rigorous demands of multiple infeeds, quick pattern changes and high uptime requirements nothing gives you the required flexibility as much as robot based automation. Remtech Systems palletizing cells utilize dedicated palletizers to eliminate potential injuries while providing guaranteed savings and a quick payback. We have a number of pre-engineered palletizing cells available specifically designed for basic to high speed applications with the ability to build upto 4 pallets simultaneously. Robotic Palletizers can handle all types of products, including boxes, cases, display trays, bags, bottles and other items. Remtech Systems also specializes in custom applications. Talk to one of our application engineers to find out how we can customize our palletizing cells to fit exactly within your facility.

Conveyor Systems

Experts in FSMA Compliance

experience and knowledge to address your needs.

Packaging Conveyors

Designing Your Optimal Conveyor System

limited, and product packaging varies. …we understand.

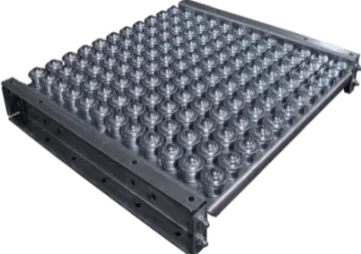

ACCUMULATION

Zero- and low-pressure

UNIT PRESENTATION

Aligning, product turning, gapping, singulating

MERGING AND TRANSFERRING

Diverting, switching

INTEGRATED CONTROL SYSTEMS

Our in-house engineers leverage integrated control systems for intuitive control, accessible

feedback and optimal performance throughout the production line.

- Mixed materials

- Irregular/unique shapes and sizes

- High throughput

- Inclines and declines

- Maintain product orientation throughout turns

• Energy efficient motor driven (24V)

• Non-driven for gravity or manual transport

• Variable accumulation pressure ranges

• Low maintenance

• Robotic cells

• Load staging

• Stretch wrapping

• Strapping