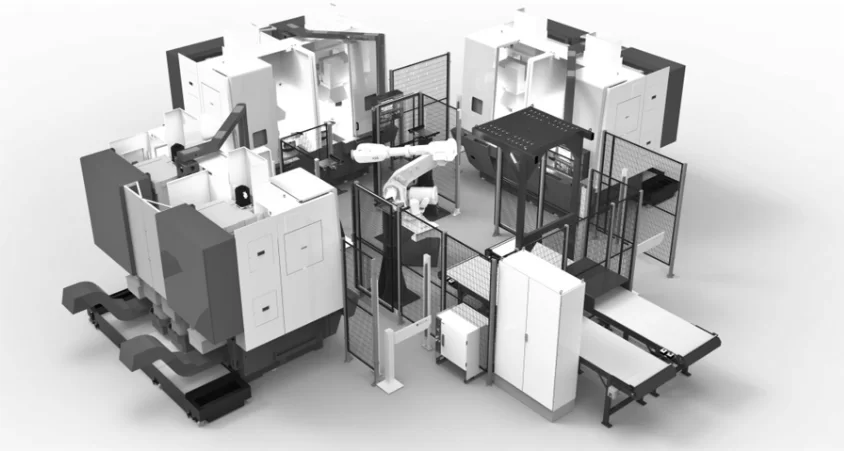

Robotic Machine Tool Tending

Identification and discrimination of different objects by using tools for image preparation, enhancement and various verification methods

Features

- Specifically designed for robot guidance

- Tight integration of control & robot communication

- Scalable up to 4 cameras

- Automatic gripping tool collision avoidance

- Simplified teach-in for lathes

- High performance vision software

- Identification and discrimination of different objects by using tools for image preparation, enhancement and various verification methods

- Proven, ready to use RAPID application code templates

- Graphical user interface with PLC integration

Benefits

- Automates one to four processing machines

- Reduces the operator time up to 60% compared to manual tending

- Can handle fragile and complex geometric work-pieces

- No need for special fixtures

- Flexible layout

FP 600

Vision-guided robotics system

- Automates one to three machines

- Highly flexible and expandable

- Handles complex and fragile components in all geometric shapes

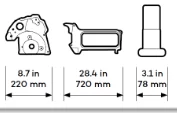

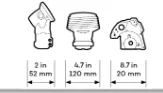

Component Examples Component size 3 -30in / 76 -760mmMax belt load customizable

Vision-guided robotics system

- Automates one to three machines

- Highly flexible and expandable

- Handles complex and fragile components in all geometric shapes

Component Examples Component size 3 -30in / 76 -760mmMax belt load customizable

FP 800

SC 3000

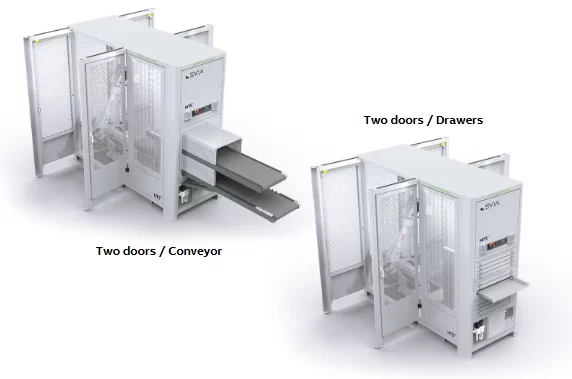

Vision-guided robotics system

- Automates one to two machines

- Choose from two feeding solutions; drawers or conveyor belts.

- One-day installation

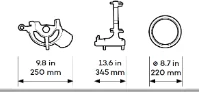

Component Examples Max height of components 8.7in/220mmMax belt load 220 lbs/ 100 kgBelt width 15.8 in / 400 mm

Vision-guided robotics system

- Can be customized with up to six post-tending processes

- Very user friendly to operate and set up for new components

- One-day installation

Component Examples Max component height 10.6in / 270mmWeight per belt 1102 lbs/ 500 kgBelt width 31.5 in / 800 mm

SC 6000

REMTECH SYSTEMS

Safety and Productivity by Design

Call us today

Or

Error: Contact form not found.